When it comes to industrial automation, every little part matters more than most people think. And if you’ve worked with robotic systems, especially where precision and speed go hand in hand, you’d already know how important it is to get the right tool holder. It’s not just about holding the tool, it’s about performance, consistency, and safety too.

But then, with so many tool holder types available and so many applications depending on specific configurations, how do you choose the right one? More so, when end of arm tooling is paired with automatic tool changers, the selection becomes even more crucial.

Let’s break this down simply. Whether you’re new to robotic automation or trying to upgrade your setup, this guide might just help you make a better choice.

Understanding the Role of Tool Holders in Industrial Automation

So let’s begin with the basics. A tool holder is what connects the robotic arm or spindle to the working tool, be it a drill, gripper, or cutting blade. Think of it like a handshake between your robotic arm and the tool it needs to function. That handshake? It needs to be solid.

In robotic systems, the connection isn’t permanent. That’s where the automatic tool changer comes in. These devices allow robots to swap tools quickly without human help. The tool holder becomes a key interface in this process, meaning you can’t really afford to get it wrong.

Some tool holders are made for precision, others for strength, and some for high-speed rotations. Depending on your automation task, the right match ensures zero compromise on performance.

Different Tool Holder Types and Where They Fit

Now here comes the trickier part. There’s no one-size-fits-all in this world of tool holder types. You’ve got collet chucks, hydraulic chucks, shrink-fit holders, and a few more. Each comes with its own pros, limitations, and ideal use cases.

- Collet chucks – Ideal when you need flexibility and lighter operations. They grip smaller tools and are pretty affordable too.

- Hydraulic tool holders – If you’re working on high precision and vibration control, these are a solid pick.

- Shrink-fit holders – Known for their incredible balance and rigidity, but they need special equipment to install/remove tools.

Depending on how often your end of arm tooling needs to change tools, and the precision required, choosing the right type becomes critical. It’s not just a technical choice – it’s also a financial and operational one.

Understanding Your Application’s Load and Speed Requirements

Before locking in your tool holder choice, consider how much load your robot arm is expected to carry and at what speed. Tool holders behave differently when handling lightweight versus heavy-duty applications. For instance, some tool holder types may excel in high-speed operations but might not hold up well under extreme loads. Analysing these parameters will help you match the end of arm tooling perfectly with the job. Getting this right ensures longer tool life, smoother operations, and minimal downtime during automatic tool changes.

What to Consider When Choosing for End of Arm Tooling

Alright, now let’s talk about end of arm tooling, or EOAT as it’s often called. This is where your robot interacts with the world. It could be a gripper, a welder, or even a paint sprayer. Choosing the right tool holder for this interface needs more than just checking the specs.

Here’s what you should consider:

- Weight – Heavier tool holders may affect the overall reach and balance of your EOAT.

- Size – It needs to fit seamlessly with both the robotic arm and the tooling system.

- Changeover Speed – If your system uses an automatic tool changer, make sure the tool holder supports fast swaps without alignment issues.

- Environment – Are you working in dusty, oily, or high-temperature zones? Choose a holder with appropriate coatings and sealing.

One small mismatch here, and your system’s efficiency could take a hit.

Matching Tool Holders with Automatic Tool Changers

Here’s where things start getting interesting. When you’ve got an automatic tool changer in the picture, your choice of tool holder becomes even more impactful.

The ATC systems are designed to work with very specific dimensions, locking mechanisms, and tolerances. If your tool holder doesn’t align perfectly, you could end up with wear and tear faster than expected, or worse, failed tool changes mid-operation.

A few tips here:

- Stick to tool holders that are certified compatible with your changer model.

- Avoid overly bulky designs that may interfere with the changer’s locking jaws.

- Ensure the tool holder is balanced for high-speed rotation, especially if you’re doing spindle-based work.

The better the compatibility, the longer your systems will run without hiccups.

Mistakes to Avoid While Choosing Tool Holders

Sometimes, even experienced engineers make decisions based on assumptions or past experiences, and it doesn’t always work out.

Here are a few mistakes that can easily be avoided:

- Ignoring tool change frequency – If you’re changing tools often, choose tool holders that allow easy alignment and locking.

- Underestimating vibration – Poor choice of holder can lead to vibrations, which directly affect tool life and machining quality.

- Mismatch with tool material – Some holders don’t do well with carbide or ceramic tools. Always check.

- Disregarding upgrade compatibility – If your line is likely to scale, pick holders that will still fit the system a year from now.

You don’t need to be a specialist to avoid these. A bit of research, a few questions to your supplier, and you’re good.

The Role of Precision in Automation Performance

Tool holders may not seem like a big deal to someone outside the automation field. But inside, we know better. The right tool holder can boost your process precision, reduce changeover time, and bring down maintenance costs over time.

When you’re working with end of arm tooling, especially in applications where repeatability matters, like electronics, automotive, or aerospace, the margin of error is small. And so the performance of even the smallest connector becomes a factor.

So yes, precision isn’t a luxury anymore. It’s standard practice. And a quality tool holder makes it possible.

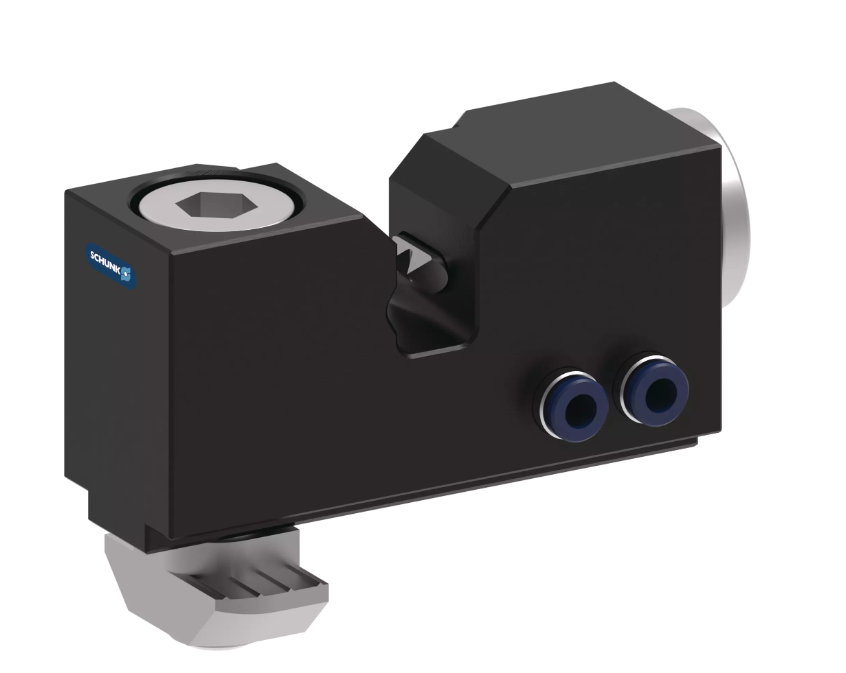

Choosing the Right Brand Partner

Lastly, don’t overlook the importance of choosing a reliable supplier. Some manufacturers offer better after-sales support, design customizations, or certifications. For instance, companies like Schunk India have built a strong reputation in automation tooling solutions, including EOAT, grippers, and advanced tool holding systems.

Whether you’re setting up a new system or just upgrading an old one, partnering with a brand that understands automation inside out can save you time, money, and effort.

Maintenance and Replacement Cycles of Tooling Components

One thing often overlooked during selection is how frequently the automatic tool changer or tool holder will need maintenance or replacement. Frequent tool changes can wear down components fast if they’re not built for the job. Look into lifecycle data and ease of disassembly when choosing. It’s not just about performance, it’s about keeping operations cost-effective and efficient over time. The right end of arm tooling should reduce unnecessary service intervals and simplify part replacements, especially when integrated with advanced systems from leaders like Schunk India.

Final Thoughts

Choosing the right tool holder isn’t just a technical decision, it’s a business one. From compatibility with your automatic tool changer to the performance of your end of arm tooling, each detail plays a role in determining your system’s productivity.

With a clearer understanding of tool holder types, their impact on precision, and how they fit into your broader automation ecosystem, you’ll be in a better position to make a choice that pays off in the long run.

So, the next time you’re evaluating options, remember, it’s not just about holding a tool. It’s about holding everything together.