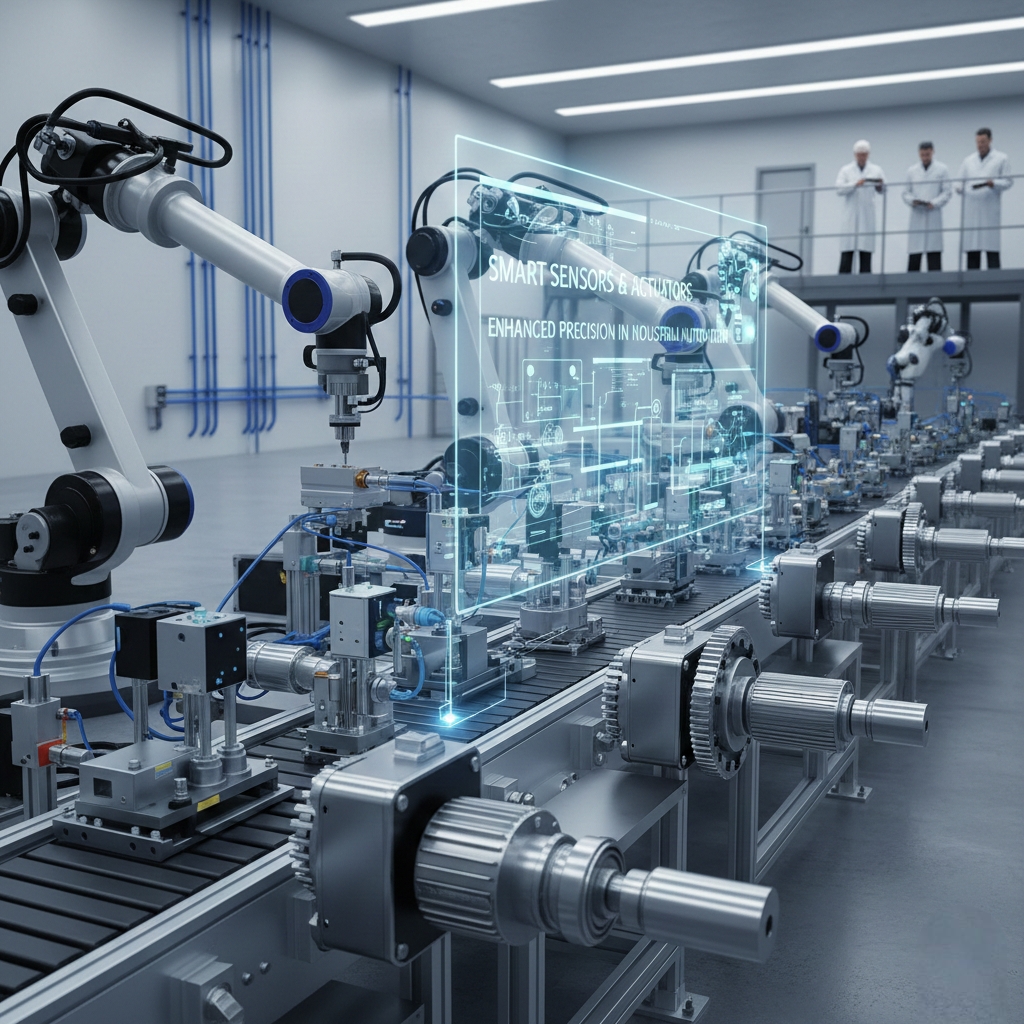

Precision has become the defining benchmark of modern industrial automation. And whether that be assembling micro parts, working with delicate components or syncing up high-speed assembly lines, industries can no longer tolerate minor variations. Enter the clever sensors and responsive actuators that in the background take subtle control. They aren’t simply storing data or navigating parts around. They help devices listen, decide and act at the precision that would have been unimaginable a decade back.

From sensing the presence of a metal part to discerning and measuring subtle force variation in a robotic arm, smart sensors are key to today’s automation systems. Here’s a look at the cocktail of sensors and actuators that work in tandem to deliver more precision, reliability and intelligence to a system.

Precision in Industrial Automation: Why it Matters

Precision in traditional manufacturing was largely the result of mechanical accuracy and competent operators. Such automation systems must, in today’s world, reproduce the same result regardless of shifts and material and environmental conditions. That level of standardization can occur only when machines are getting precise, real-time feedback.

File In smart sensors are the “eyes and ears” of automation systems. Actuators, by contrast, are the “muscles” that translate actions into movement. As a pair, they act to provide the positive feedback that enables automated systems to self-correct, adapt and hold tight tolerances.

Sensors in Intelligent Automation

In the most simplistic terms, sensors sense different changes in their surrounding and turn them into electrical signals. In wise automation sensors proceed even farther. Provide fast, reliable and often continuous data that machines use to understand what is going on at each stage of the process. Below are some of the most common types of sensors that directly impact accuracy.

Inductive Proximity Sensors: Dependable Metal Detection

With just about a century of industrial know-how, these days sensors are a major part of any process.

An inductive proximity sensor is a non-contact sensing device. It operates by emitting an electromagnetic field and detecting a response from objects made of metal within the vicinity. This makes it perfect for dirty or rough industrial environments where dust, oil splashing, or vibration would destroy similar mechanical switches.

Inductive sensors are commonly used for:

- Position detection in CNC machines

- End-of-travel sensing in actuators

- Counting metal components on conveyor lines

Because there’s no physical contact, wear and tear are minimal. That reliability directly translates into consistent positioning and improved process accuracy.

Metal Proximity Sensors in Heavy-Duty Applications

A metal proximity sensor is essentially a category that includes inductive sensors specifically optimized for detecting metal parts. These sensors are widely used in automotive, metalworking, and heavy manufacturing industries where components are often rough, oily, or exposed to temperature variations.

Their biggest advantage lies in consistency. Even when conditions fluctuate, metal proximity sensors maintain stable sensing distances, ensuring machines always know exactly where a component is located.

PNP Proximity Sensors and Signal Stability

A PNP proximity sensor refers to the output configuration rather than the sensing method itself. In a PNP setup, the sensor supplies a positive signal to the control system when activated. This configuration is widely preferred in modern automation due to its noise resistance and compatibility with PLC systems.

PNP sensors help improve precision by:

- Reducing false signals

- Offering cleaner integration with control logic

- Improving safety diagnostics

When precision depends on split-second decisions, signal clarity becomes just as important as detection accuracy.

Analog Proximity Sensors: Measuring Distance, Not Just Presence

Unlike standard on/off sensors, an analog proximity sensor provides a continuous output signal proportional to distance. Instead of simply telling the system whether an object is present, it tells how far away it is.

This capability is crucial for:

- Fine positioning tasks

- Tool wear monitoring

- Height and thickness measurement

In high-precision automation, analog proximity sensors allow machines to make micro-adjustments in real time. This is especially valuable in applications like robotic assembly or adaptive machining, where tolerances are extremely tight.

From Detection to Action: The Role of Actuators

Sensors provide information, but actuators are responsible for executing decisions. In industrial automation, actuators convert electrical, pneumatic, or hydraulic signals into controlled motion.

Precision in actuation is no longer just about movement. It’s about controlled force, speed, and position, often all at once.

Force and Torque Sensors: Giving Machines a Sense of Touch

A force and torque sensor plays a unique role in automation by measuring how much force or rotational load is being applied. Unlike proximity sensors that detect presence or distance, these sensors measure interaction.

They are widely used in:

- Robotic gripping and assembly

- Quality inspection systems

- Human-robot collaboration

By integrating force and torque sensing, machines gain a form of tactile awareness. For example, a robotic arm can detect if it’s applying too much pressure during assembly and instantly correct itself. This dramatically reduces defects and component damage.

Precision in Robotics Through Sensor-Actuator Integration

Robotic systems are where smart sensors and actuators truly shine. A robot equipped with proximity sensors knows where objects are. Add force and torque sensing, and it understands how those objects respond to contact.

This combination allows robots to:

- Adjust grip strength dynamically

- Detect misalignment during assembly

- Safely interact with humans

Without this level of feedback, robots would rely solely on pre-programmed paths, which limits flexibility and increases risk.

Smart Sensors in Closed-Loop Control Systems

Modern automation relies heavily on closed-loop control. In these systems, sensor feedback continuously informs actuator behavior. If something changes, load, position, or speed, the system compensates instantly.

For example:

- An analog proximity sensor detects a slight height variation

- The controller processes this data

- An actuator adjusts position in real time

This constant feedback loop is what enables micron-level precision in today’s automated processes.

Reliability and Repeatability on the Shop Floor

Precision isn’t just about being accurate once. It’s about repeating the same result thousands of times. Smart sensors improve repeatability by minimizing external influences like vibration, temperature, and electrical noise.

PNP proximity sensors, for instance, help maintain stable signals even in electrically noisy environments. Inductive and metal proximity sensors continue working reliably despite dust and oil. Force and torque sensors ensure consistent interaction forces across production cycles.

Data-Driven Precision and Industry 4.0

Smart sensors are also key enablers of Industry 4.0. Many modern sensors provide digital outputs, diagnostics, and connectivity to higher-level systems.

This allows manufacturers to:

- Monitor sensor health

- Predict failures before they happen

- Optimize processes using real-time data

Precision, in this context, extends beyond physical movement to data accuracy and system transparency.

Choosing the Right Sensor for the Right Task

Not every application requires the same sensing technology. Precision comes from selecting the right sensor for the job:

- Use an inductive proximity sensor for reliable metal detection

- Choose an analog proximity sensor when distance matters

- Opt for a PNP proximity sensor for clean PLC integration

- Integrate force and torque sensors for sensitive handling and assembly

A well-designed automation system often uses multiple sensor types working together.

Role of Schunk India in Precision Automation

At the advanced automation end of the market, Schunk India also has a solid reputation for high quality gripping as well as clamping and sensor solutions. Their expertise extends to high-precision sensor and actuator technology developed for the specific requirements of contemporary industry.

By emphasising on reliability, accuracy and ease of integration, Schunk India helps manufacturers who want to take the next step in breaking through standards of precision automation with the view of long-term stability.

Future Trends in Smart Sensors and Actuators

Looking ahead, sensor and actuator technology will continue evolving toward:

- Smaller, more integrated designs

- Increased use of AI for adaptive control

- Greater connectivity and self-diagnostics

- Enhanced safety for collaborative automation

As automation systems become more intelligent, the line between sensing and actuation will blur even further.

Final Thoughts

Where precision in industrial automation originates from is “not a single component. It is powered by the intelligent interplay of smart sensors and actuators. Features from the reliable sensing of an inductive proximity sensor to complex feedback delivered by a force and torque sensor all contribute to the building of precise, dependable systems.

With the right sensor technologies, such as metal proximity sensors, PNP proximity sensors and analog proximity sensors along with intelligent actuation, manufacturers can realize higher quality outcomes with less waste and more flexibility.

Smart automation always comes back to one thing i.e., not replacing human skill. It’s the attempt to hardwire precision into machines, to ensure that everything moves, measures, and decides as it should.