The services provided in precision stamping, injection molding, and printing companies are high quality and reliable with regard to the production of automotive and industrial parts. These are ways to make a component all-round and precisely done, which leads into them being strong, detailed, and consistent in each part.

Change concepts into resilient, high-output components via our advanced stamping, molding, and printing services. Tailored to high speed, strength, and precision, this was ideal in automotive and industrial innovations.

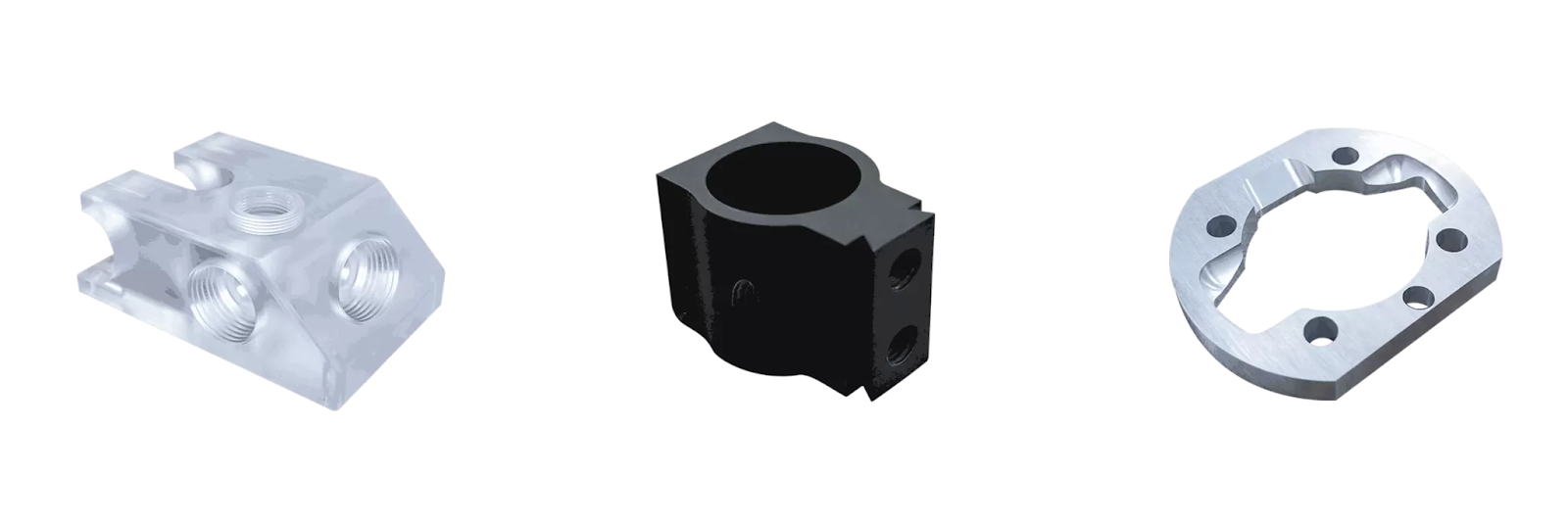

Our injection molding, printing, and precision stamping automotive parts services carry custom-engineered parts that are systematically designed to be performance friendly and dependable. From metal shapes to plastic shapes and sharp prints, we design solutions that are ideal for automotive and industrial quality.

The Importance of Precision Stamping

Precision stamping is important since it produces high-quality, repeatable, and precise metal parts at high speed and with low waste. It forms even the multiple designs using custom dies and high-speed forms smoothly with edges and precise dimensions. It is an easy choice when it comes to heavy-duty yet lightweight car and industrial construction.

Precision stamping is a highly accurate production technology employed in producing parts by means of potent presses and custom dies employed on metal sheets to create dramatically complicated parts in high precision and repeatable steps. The key advantages of it are

- Blistering speed of production—stamp out thousands of parts per hour.

- Precise tolerances—precise designs to successful assembly

These strengths have made it best suited to the manufacture of metal clips, brackets, shims, and structural parts where detail and strength are important.

Plastic Injection Solutions Smart

The rapid production of complex parts is created in a clever way due to plastic injection molding. It can shape molten plastic into fine detail; it is thus suitable for a range of things, such as automotive clips and the housing of consumer devices.

The process also accommodates a vast variety of various materials and finishes, which enables one to have strong, lightweight, and durable plastic injection service parts. The waste is low and the repeatability is high, so it is an intelligent choice in high-volume production.

Printing Services: Automatic Marking

High-quality printing techniques like pad, laser, and digital UV printers apply logos, serial numbers, instructions, or decorative designs on completed parts. Benefits include:

- Customization: branding or traceable parts Customization Ways to customize parts: Personalized parts

- Resistance: heat, chemicals, and abrasion-resistant printed service markings

- Professional polish: head-up images that are clean and crisp and enhance presentation

Marking occurs before and after manufacturing by means of printing in order to make parts identifiable, attractive, and completely traceable as well as functional.

One-Stop Production: A Smooth Production

Separating stamping, molding, and printing into an integrated process enhances efficiency and quality control. Here’s how:

- Design and engineering

The engineers work together to study the functioning of parts, choice of materials, and optimal tooling of stamping or moldings.

- Test & Prototype

Some early models are manufactured to test form, fit, and functionality prior to total production commencing.

- Tooling & Setup

The dies and molds used are precision, and the dies and molds undergo testing and calibration to suit the environment of production.

- High-Volume Production

With the approvals, the gears are now in full manufacturing with uninterrupted monitoring.

- Post-processing & Printing

Components are deburred, acquire a surface finish, and are printed with logic, numbers, or instructions on them.

- Quality Inspection

High essential metrics, material quality, and print accuracy are approved through QC tests.

- Final Packaging

Parts are cleaned, wrapped, and sealed as they are shipped worldwide, all set to be incorporated or assembled.

Quality on All Levels

Serious quality procedures are the beginning of protecting your brand and assured product performance.

- Auditation of die and mold prior to production

- Monitoring during a process in order to maintain the process stability

- Dimensional compliance statistical sample Statistical sample of dimensional compliance

- Electrophotographic testing at different conditions

- Complete evaluation reports are attached to every shipment.

These QA checks guarantee quality products of industry standards in the automotive, appliance, electronic, and machine industries.

The industries we serve

Our services are offered to a wide range of domains, which are

- Auto: engine parts, trim, connectors, brackets

- Industrial Equipment: valve equipment, panels, sensor mounts

- Medical devices: exact printed signs, metallic supports

- Home Appliances: metal springs, buttons of plastic, and logo

Metal Stamping in Detail (Step-by-Step)

- Tool & Die Design – Utilize CAD part drawings to create stamping tools

- Die Fabrication – Hardened Steel Dies machined to tight tolerances

- Setup—Install die in HSP and trial run blanks.

- Shearing – shape dies Shearing Blanking Shearing/Blanking: cutting part from sheet before forming

- Progressive or Transfer Stamping—For complex geometry multi-stage forming

- Parting out—The part is removed from the stamping with punches or by air blast.

- Deburring & Cleaning – Remove burrs and sharp edges for safe handling

In this multi-step process, every single metal component is tested to the same specification and standard.

SEO Keywords Seamlessly Integrated

And of course, the content includes plenty to keep keyword-driven global SEO stats up.

precision metal stamping

plastic injection molding

industrial printing services

automotive part manufacturing

custom stamping and molding

durable printed parts

high-volume manufacturing

Conclusion

End paper precision stamping, injection molding, and printing complete the triad for manufacturing fine automotive and industrial parts. They guarantee each and every part is manufactured with a precision touch, durability, and a fine finish.

With advanced manufacturing technology, companies can cut production time and costs while enjoying similar results. Such integration opens up new realms of efficiency and innovation to different fields worldwide.

FAQs:

What is used in precision stamping?

Mostly, metal sheets and thin slabs of steel, aluminum, copper, cobalt, and bronze can be considered.

What degree of complexity can parts produced by injection molding manipulate?

Injection molding has developed very complex geometrical configurations with a high level of regularity.

What printing techniques do you have for parts?

We offer laser marking, pad printing, and UV printing as options for identification and marking on parts.

Will you be catering for small and big production runs?

Of course, we can handle prototypes and mass manufacturing all at once.

Are the printed marks wear-resistant?

To be brief and to the point, the mechanical properties of the symbols are such that they are expected to exhibit abrasion resistance similar to what other heaters and material coatings demonstrate.