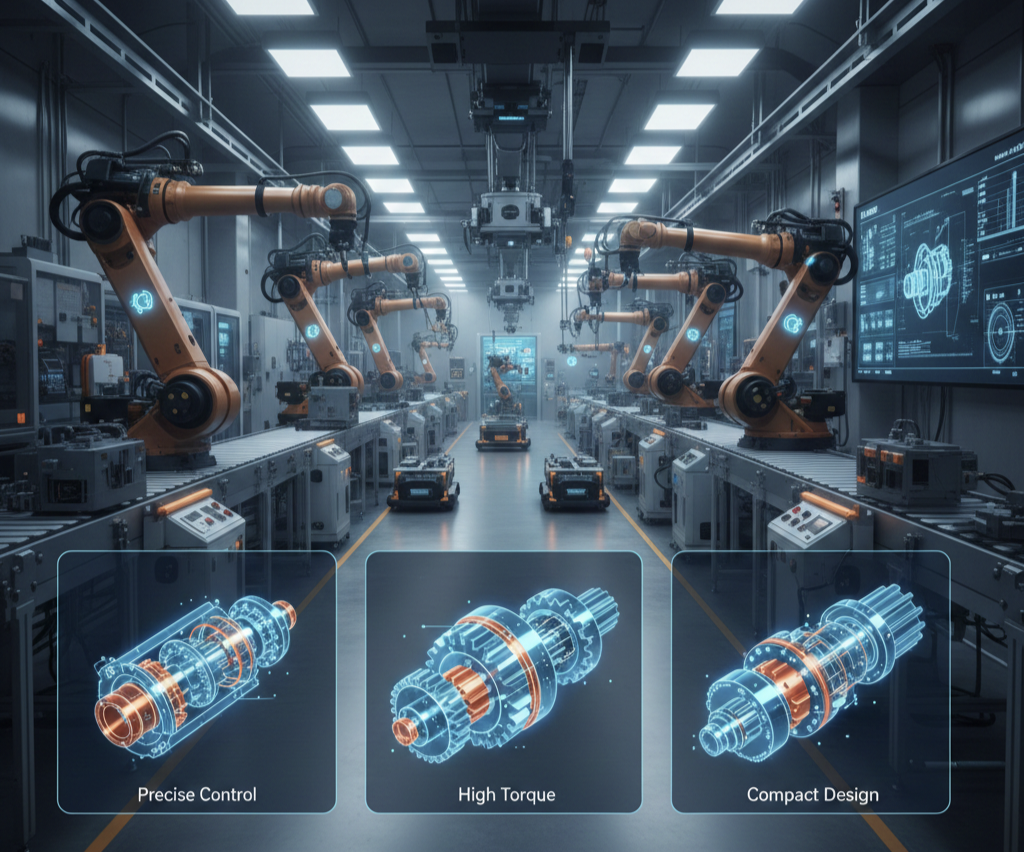

Walk into any modern factory, and you will see one thing right away: it is not always obvious what the workers do. Robot arms rotate to stack components, conveyor systems position parts for indexing at just the right moment, inspection stations tilt components into scanning position and packaging lines pivot products into place. Beneath this smooth, synchronized movement lies a silent workhorse, rotary actuators.

They may not command headlines the way robots or artificial intelligence do, but it’s precisely rotary actuators that get automated motion done. Without them, there would be no easy turning; no repeatable position; no stable rotation. In other words, much of modern automation would cease to function.

Let’s explore just what rotary actuators are, their place in modern automated systems, and specifically why incarnations such as the 180 degree rotary actuator, micro rotary actuator, small rotary actuator or semi rotary actuator have become invaluable in so many different marketplaces.

Understanding Rotary Actuators in Simple Terms

At the most basic level, rotary actuators are power-driven devices that transform energy, whether pneumatic, hydraulic, or electric, into controlled rotational motion. Unlike their linear counterparts, which move back and forth in a straight line, rotary actuators produce angular movement. This could be a small partial turn or a full rotation, depending on the design.

For most industrial applications, continuous spinning like a motor provides isn’t necessary. Instead, exact and repeatable angles are required, opening a valve, turning a component, aligning a sensor, or indexing a workholding fixture. That’s precisely where rotary actuators excel.

They deliver:

- Accurate angular positioning

- Consistent torque

- Compact motion control

- Reliable repeatability

From massive production lines to compact robotic cells, rotary actuators are everywhere.

Why Rotary Actuators Matter in Modern Automation

Automation today is built around speed, accuracy, and flexibility. Manufacturers expect machines to run nonstop, switch between products quickly, and maintain tight tolerances. Rotary actuators support all of this by enabling controlled rotation without complex mechanical linkages.

Here’s what they bring to the table:

- Faster cycle times through direct rotational movement

- Reduced mechanical complexity

- Higher positioning accuracy

- Lower maintenance compared to traditional gear systems

- Easy integration with sensors and controllers

In many setups, replacing bulky mechanical assemblies with rotary actuators simplifies design while improving performance. That’s a big reason their adoption keeps growing.

The Role of Rotary Actuators in Robotics

Automation and robotics go hand in hand, and robotics actuators are the muscles that bring robots to life. Rotary actuators play a central role in robotic joints, grippers, wrists, and rotary tables.

In robotic systems, actuators must deliver:

- Smooth motion

- Precise stopping points

- Compact size

- High reliability

Whether it’s a collaborative robot assembling electronics or an industrial robot welding car frame, rotary actuators help control movement with millimeter-level accuracy.

Smaller robots often rely on a micro rotary actuator or small rotary actuator to fit into tight spaces while still delivering usable torque. Larger robots may use heavier-duty rotary units for handling payloads.

Either way, without rotary actuators, robotics as we know it simply wouldn’t function.

Different Types of Rotary Actuators Used in Automation

Not all rotary actuators are built the same. Different applications demand different motion profiles, sizes, and torque outputs.

Let’s explore some common varieties.

Semi Rotary Actuator

A semi rotary actuator is designed for limited-angle rotation, typically between 90° and 270°. These are extremely common in industrial automation, especially for:

- Opening and closing valves

- Indexing parts

- Positioning components

- Flipping products on conveyors

They offer precise end stops and repeatable motion, making them ideal for pick-and-place systems and assembly lines.

180 Degree Rotary Actuator

The 180 degree rotary actuator is a popular choice when applications require a full half-turn. You’ll find them in:

- Part flipping stations

- Packaging lines

- Orientation systems

- Inspection setups

This type of actuator allows components to be rotated exactly halfway, ensuring consistent alignment for downstream processes.

Micro Rotary Actuator

As automation moves toward miniaturization, the micro rotary actuator has become increasingly valuable. These compact units are designed for:

- Electronics assembly

- Medical devices

- Precision instruments

- Small robotic grippers

Despite their size, micro rotary actuators still deliver impressive control and repeatability. They’re proof that automation doesn’t always mean big machinery.

Small Rotary Actuator

Sitting between micro and standard models, the small rotary actuator is widely used in light industrial applications. They’re compact enough for tight spaces but strong enough for tasks like:

- Sorting

- Indexing

- Light material handling

- Fixture positioning

Their balance of size and performance makes them a favorite in modular automation cells.

How Rotary Actuators Improve Productivity

Productivity in automation isn’t just about speed, it’s about consistency, uptime, and quality. Rotary actuators contribute on all fronts.

Reduced Cycle Time

Direct rotational movement eliminates extra mechanical steps. Instead of converting linear motion into rotation, actuators provide rotation directly, saving time every cycle.

Improved Accuracy

Modern rotary actuators offer precise angular control, reducing positioning errors and improving product quality.

Compact System Design

Using actuators instead of complex gear assemblies frees up space and simplifies machine layouts.

Lower Maintenance

Fewer moving parts mean less wear and fewer breakdowns. That translates into higher uptime and reduced maintenance costs.

Applications Across Industries

Rotary actuators are used across nearly every automated sector.

Manufacturing: They handle indexing tables, tool changers, and assembly stations.

Automotive: From welding fixtures to inspection platforms, rotary actuators help maintain speed and precision.

Packaging: They rotate, orient, and position products at high speed.

Electronics: Micro and small rotary actuators support delicate assembly tasks.

Medical Devices: Compact rotary motion is essential for precision manufacturing and testing.

No matter the industry, the requirement is the same: reliable rotation with minimal fuss.

Integration with Sensors and Control Systems

Modern rotary actuators don’t work in isolation. They’re typically paired with:

- Position sensors

- Limit switches

- Encoders

- PLC systems

This allows real-time feedback and closed-loop control. In robotics actuators, this integration ensures joints move exactly where commanded and stop precisely when required.

Smart actuators now even provide diagnostic data, helping predict maintenance needs before failures occur.

Electric, Pneumatic, or Hydraulic?

Rotary actuators come in different drive types:

- Pneumatic actuators are fast, simple, and cost-effective

- Electric actuators offer precise control and programmability

- Hydraulic actuators provide high torque for heavy-duty tasks

Each has its place. Smaller automation setups often prefer electric or pneumatic solutions, while large industrial machinery may still rely on hydraulics.

Why Compact Actuators Are Gaining Popularity

The shift toward modular and flexible automation has increased demand for micro and small rotary actuators. Manufacturers want systems that:

- Fit into compact cells

- Can be reconfigured easily

- Support collaborative robots

- Reduce overall machine footprint

This trend explains why the micro rotary actuator and small rotary actuator markets are growing so quickly.

Smaller doesn’t mean weaker anymore. Advances in materials and design now allow compact actuators to deliver serious performance.

Common Challenges and How Rotary Actuators Solve Them

Automation engineers often face issues like:

- Limited installation space

- Complex mechanical layouts

- Inconsistent positioning

- Excessive maintenance

Rotary actuators address these challenges by offering direct motion, compact form factors, and reliable operation. A single semi rotary actuator can replace multiple mechanical components, simplifying the entire system.

The Future of Rotary Actuation

Rotary actuator technology continues to evolve. Some trends shaping the future include:

- Integrated electronics for smarter control

- Lightweight materials for robotics

- Higher torque density in compact sizes

- Built-in sensing and diagnostics

As factories move toward Industry 4.0, rotary actuators will become even more intelligent, feeding performance data into automation platforms for continuous optimisation.

Final Thoughts

Controlled motion is the lifeblood of modern automation, and rotary actuators work right at the heart.

These applications range from heavy industrial equipment to precision robotics, providing precise turning, faster cycle times, and space-efficient machine design. Finally, no matter what it is (such as a 180 degree rotary actuator flipping parts or a semi rotary actuator indexing parts or even the micro rotary actuator of precision robotics), all has its important purpose.

All that combined with the increasing relevance of robotics actuators and this much is certain: rotary actuators aren’t simple parts, they are enablers of efficiency, reliability, and innovation.

One thing is clear as automation evolves. The need for smarter, smaller and more powerful rotary actuators will continue to grow.